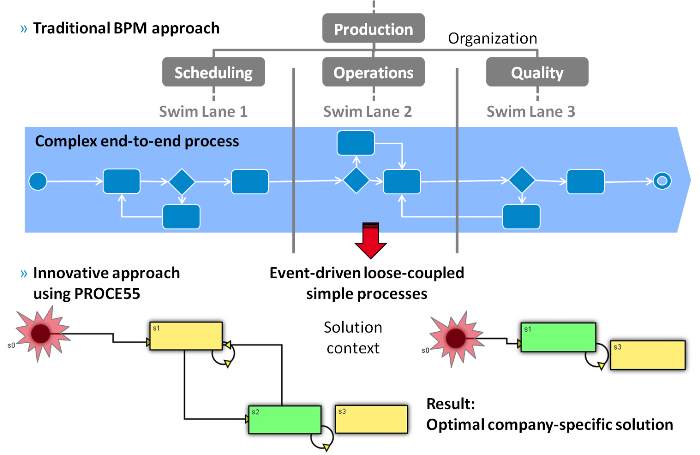

Business Process Management (BPM) introduced model-driven process execution paradigm into the process automation and system integration. Using BPM, business professionals together with IT experts can implement company-specific solutions as a competitive advantage of the company. Business agility can be improved when complex processes are decomposed into an integrated set of loose-coupled event-driven simple processes.

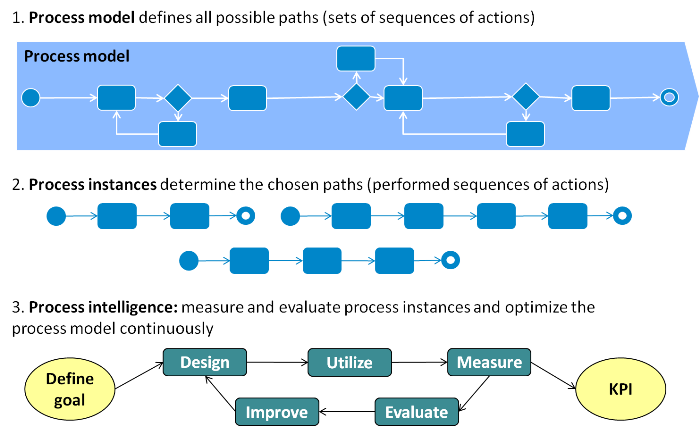

Once a company-specific solution has been implemented, business professionals can optimize business processes continuously. Process Intelligence (PI) tools and techniques help to understand the business processes and use them effectively. PI provides an objective performance assessment and identifies areas for improvement. Key Performance Indicators (KPIs) are measurement points that allow for analysis, benchmarking and optimization of processes.

Using PROCE55, any business process can be automated and any system integrated. We are focusing on the areas of manufacturing and logistics using our knowledge and real experience.

Our knowledge and practical experience allow East-Gate to focus on the areas of production, logistics and maintenance.

The challenge in the manufacturing companies

In these areas we have developed pre-configured applications and components, which significantly accelerate deployment into production environment.

Today, business process automation with standard ERP software is not optimal especially at the shop floor because of the following reasons:

- company-specific functionality is missing (e.g. traceability, quality control, production data collection, etc.),

- effort for performing ERP transactions is high, user interface and application navigation are complex,

- flexibility in process control is low,

- specific checks are missing - mistakes can occur,

- ERP does not measure process performance.

Therefore company-specific solution needs to be implemented.