Overview

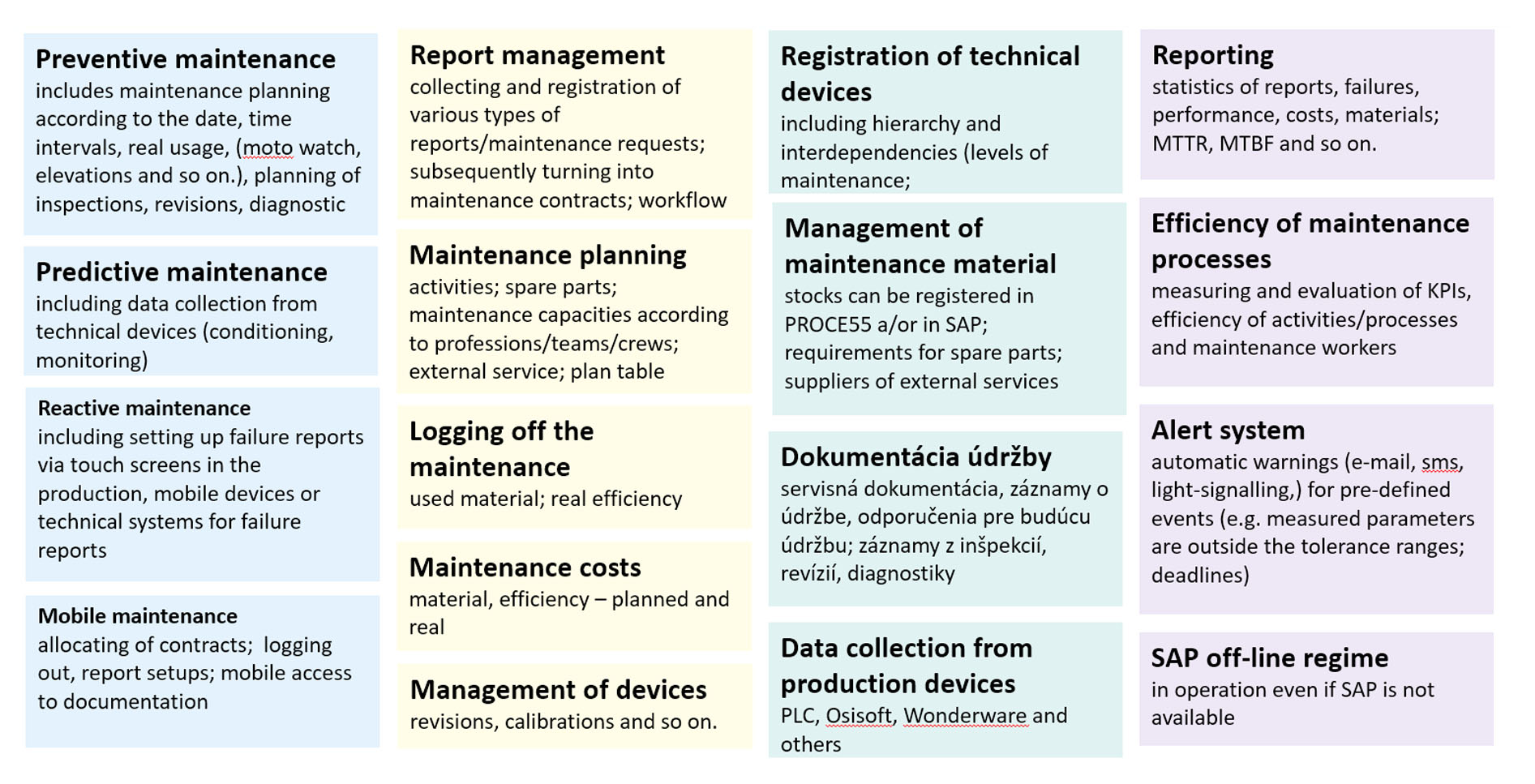

PROCE55 Maintenance functionality covers all requirements of modern maintenance management in a production plant.

Basic functionality of PROCE55 can be deployed very quickly and flexibly. It is easily adaptable to customer needs. Its great advantage is the possibility to add specific functions necessary for the customer. PROCE55 is based on the unique BPM (Business process management) technology, which allows further work on the functionality.

Thus, the customer can use benefits of this solution very quickly and expand it gradually.

Management of PROCE55 Maintenance application

It covers all management functions of machines and equipment master data, spare parts, warehouses, external suppliers of spare parts and services, maintenance services, documentation and user licences. Including loosely defined organization and warehouse management structures, hierarchical structures of machinery, equipment and spare parts.

Machinery and equipment

A simple overview of location, machinery and equipment structure, parameters, related spare parts and maintenance activities. Knowledge database.

Spare parts, warehouse management and external maintenance

Effective spare parts and warehouse management ensures, that spare parts are available on time, at the right place and in required quantity. Transparent consumption, turnaround evaluation and management of spare part orders reduce inventory levels. Using 1D/2D codes or RFID tags as the means of identification enables simple and quick inventory. Enter your requirement of spare parts acquisition or external maintenance quickly and easily. Get an overview of external maintenance activities and eliminate unjustifiably accounted operations.

Notifications and creating requests

Simple and immediate entry of notifications or maintenance requests; through web interface or mobile device. Machine part or spare part identification by reading 1D/2D code, RFID or NFC. Possibility of adding photo or video documentation to a notification.

Maintenance planning

Automatic maintenance order planning according to previously set criteria and manual ad-hoc planning as needed. A planning table clearly displays planned, currently running and completed actions. Unlimited planning date range. Spare part availability overview. Capacity overview.

Maintenance

Efficient and user-friendly PROCE55 Maintenance application helps with planning, management and overview of maintenance tasks. It includes all important areas such as inspection, notifications, maintenance, repairs or legally required auditing. Automatic planning improves your processes.

Process performance and time measurement (repair start time, repair duration) serve as a tool for continuous process optimization.

Predictive maintenance

Creating notifications or maintenance orders based on data collected from machines or inspections and relevant established parameters for their evaluation. The application prevents unexpected failures and, if needed, extends spare parts replacement intervals.

Mobile maintenance

Simple notification creating via a mobile device shortens response time and significantly lowers the risk, that the notification will be later left out of the system. The application identifies machine parts or a spare part by reading 1D/2D code, RFID or NFC. Possibility to add photo or video documentation to a notification or order. Assigning orders via mobile device shortens response time. Documentation available via mobile devices accelerates the maintenance process. Ability to search, display and reserve a particular spare part. Supports auditing and inspections.

Key indicators and visualization

PROCE55 applications record discrete data and thus enable immediate and backward analysis of particular event parameters and subsequently allow their statistical processing into key parameters such as MTBF, MTTR, repair start time and repair duration, etc..

Based on the calculated statistics of analyses and key indicators, information for management is prepared appropriately for correct and timely decisions and continuous process improvement.

Measuring and evaluation of maintenance task performance in regard to prescribed, i.e. planned time. Visualisation of the current situation in production and maintenance.

Knowledge database and documentation

Technical documentation related to machines and equipment, records of maintenance activities and measures are easily accessible. The knowledge database unites information acquired during identification processes and failure causes with subsequent activities performed on the machinery or equipment. It is possible to add multimedia information. Comfortable contextual information search. Immediate access to information for authorized users via mobile devices anywhere.